Panduan Keamanan Mesin Pengupas Bawang Putih

1. Sebelum menggunakan mesin pengupas bawang putih, pastikan firmware telah dikencangkan, bagian yang berputar fleksibel, dan terdapat cukup minyak di bantalan, dan mesin pengupas ditempatkan dengan stabil. Untuk menjamin keselamatan operator, penutup motor harus menggunakan sambungan ground (penutup motor harus tersambung dengan baik ke konektor ground).

2. Nyalakan mesin pengupas bawang putih beberapa kali sebelum listrik menyala. Jika ada suara tabrakan, cari tahu kembali penyebab dan kekuatannya.

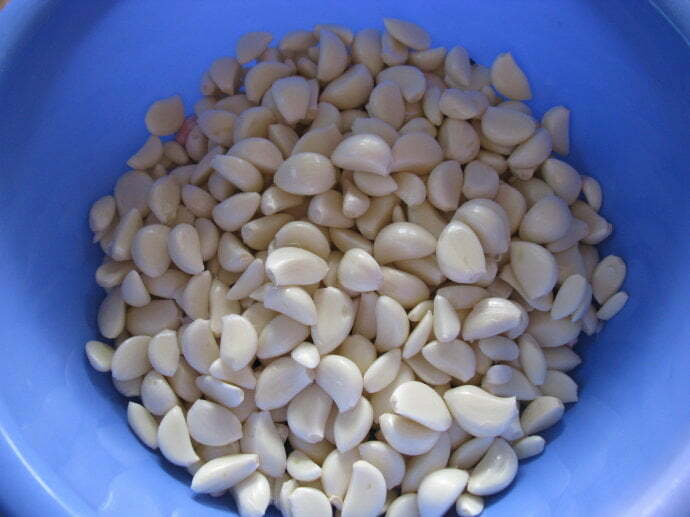

3.Pilih jaring ayakan yang sesuai dengan ukuran biji bawang putih.

4.Setelah memberi energi, rotor harus diuji dan pastikan rotor berputar dengan benar. Setelah motor hidup, arah rotor harus sesuai dengan arah yang tertera pada mesin. Tuang kacang tanah ke dalam hopper secara kuantitatif, seragam dan terus menerus setelah motor idle selama beberapa menit tanpa ada suara yang tidak normal dan pengoperasiannya normal dan stabil.

5.Solusi untuk menambah jumlah pengupasan bawang putih adalah dengan menggerakkan motor ke bawah sehingga mengencangkan sabuk kipas kemudian menambah volume udara.

6. Saat mengupas, inti bawang putih harus dimasukkan secara merata dan benar, dan potongan besi, batu, dan serba-serbi lainnya tidak boleh tercampur, untuk menghindari pecahnya siung bawang putih atau menyebabkan kecelakaan mekanis. Buka saklar keluar ketika saringan sudah tertutup siung bawang putih.

7. Setelah digunakan, sebelum menyimpan mesin pengupas bawang putih, harus bersih dari debu, kotoran dan sisa butiran bagian dalam dan lain-lain, lalu cuci seluruh bagian bantalan dengan solar, lalu biarkan kering setelah dilapisi mentega, lalu cat bagian yang dicat, dan biarkan kering. Setelah itu, tutup mesin, dan simpan di gudang kering. Sabuk harus dilepas dan digantung di dinding yang kurang ajar.