Produktionslinie für Knoblauchpulver

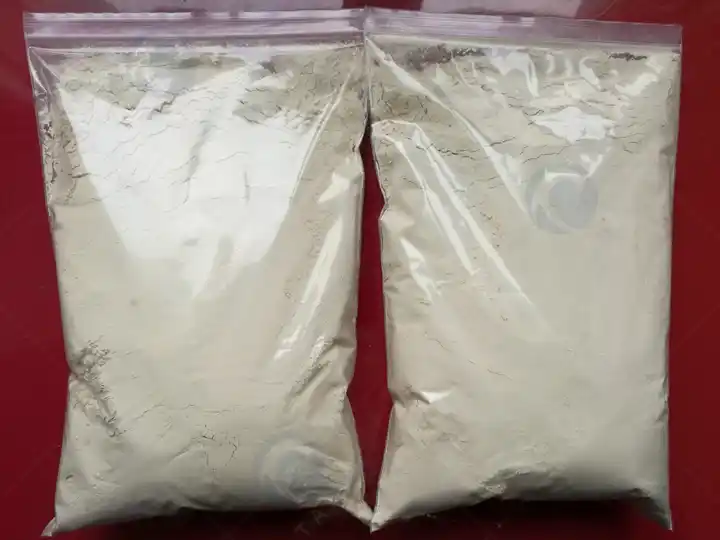

Knoblauchpulververpackungsmaschine | Automatische Knoblauchpulververpackungsmaschine

Die Knoblauchpulver-Produktionslinie gewinnt getrocknetes Knoblauchpulver aus rohem Knoblauch. Sie durchläuft hauptsächlich die Prozesse Knoblauchzehen-Trennung, Schälen, Schneiden, Reinigung, Dehydration, Mahlen und Verpacken.

Das durch die Knoblauchpulver-Produktionsanlage gewonnene Knoblauchpulver hat eine einheitliche Feinheit. Und das endgültige Knoblauchpulver ist verpackt, was den Transport und die Lagerung erleichtert. Die Maschinen dieser Knoblauchpulver-Produktionslinie können auch separat gekauft und verwendet werden.

Warum sollte Knoblauch zu Knoblauchpulver verarbeitet werden?

Unter Knoblauch-Tiefverarbeitung versteht man Knoblauchprodukte, die durch bestimmte Verarbeitungstechniken aus rohem Knoblauch hergestellt werden. Zu den tief verarbeiteten Knoblauchprodukten gehören Knoblauchpulver, Knoblauchscheiben, Knoblauchbrei, schwarzer Knoblauch, Knoblauchöl und andere Produkte. Tiefverarbeitete Knoblauchprodukte können die Verwertungsrate von Knoblauch erhöhen und größere wirtschaftliche Vorteile erzielen. Das durch Dehydrieren und Mahlen hergestellte Knoblauchpulver hat die Funktion, die Durchblutung zu fördern, Blutstauungen zu beseitigen, Hitze zu beseitigen und zu entgiften. Im Vergleich zu Knoblauch ist Knoblauchpulver bequemer zu essen.

Verfahren zur Herstellung von Knoblauchpulver

Der Produktionsprozess von Knoblauchpulver besteht darin, dass die Knoblauchzehen getrennt, geschält, gereinigt, geschnitten, dehydriert, gemahlen und verpackt werden.

Trennen Sie die ganze Knoblauchzehe in einzelne Knoblauchzehen und entfernen Sie dann die äußere Haut des Knoblauchs. Schneiden Sie den ganzen Knoblauch in Scheiben, verwenden Sie einen Dörrautomaten, um ihn zu dehydrieren, mahlen Sie ihn und verpacken Sie ihn. Dann können Sie das fertige Knoblauchpulver erhalten.

Beschreibung der Maschinen zur Verarbeitung von Knoblauchpulver

Knoblauchzehentrennmaschine

Ein Knoblauchzehentrenner ist eine Maschine, die verwendet wird, um Knoblauchzehen zu trennen. Sie ahmt hauptsächlich die manuelle Handlung von Menschen nach, die die Knoblauchzehen reiben, um sie zu trennen. Der Hauptzweck der Verwendung dieser Maschine zur Trennung von Knoblauchzehen besteht darin, das Schälen von Knoblauch zu erleichtern. Diese Maschine wird häufig für Knoblauchzehen unterschiedlicher Größen verwendet.

Knoblauchschälmaschine

Entsprechend der unterschiedlichen Knoblauch-Produktionskapazitäten gibt es zwei Arten von Knoblauchschälmaschinen: kleine und Kettenplatten-Schälmaschinen. Beide dieser beiden Knoblauchschälmaschinen verwenden das gleiche Schälprinzip, nämlich das Schälen mittels Drucklufttechnologie. Die automatische Knoblauchschälmaschine wirkt auf das Schälen von getrocknetem Knoblauch. Und sie hat keine Anforderungen an die Sorte und Größe von Knoblauch.

Die Shuliy-Verpackungsmaschine bietet automatisches Wiegen, Beutelbildung, Füllen, Versiegeln, Schneiden, Fehlererkennung mit Alarmen sowie Codierung/Tintenstrahldruck. Sie unterstützt auch maßgeschneiderte Zusatzfunktionen wie Stickstofffüllung, Staubentfernung und automatische Zuführsysteme.

Die Knoblauchreinigungsmaschine simuliert manuelle Reinigungsaktionen durch eine Wasserbadblasenreinigung. Sie transportiert sanft, ist geschwindigkeitsverstellbar und kann effektiv vermeiden, dass der Reinigungsprozess den Knoblauch berührt, anstößt, zerkratzt oder anderweitig beschädigt, wodurch die Effizienz der Arbeit verbessert und die manuelle Arbeit durch mechanisierte Verarbeitung ersetzt wird.

Knoblauchschneidemaschine

Der Knoblauchschneider verwendet einen multifunktionalen Wurzelgemüseschneider. Er kann zum Schneiden von Kartoffeln, Gurken, Taro, Yamswurzeln, Ingwer und anderen Rohstoffen verwendet werden. Darüber hinaus sind die vom Gerät geschnittenen Knoblauchscheiben gleichmäßig dick, die Schnittfläche ist glatt und die Schneidgeschwindigkeit ist schnell. Die gesamte Maschine besteht aus lebensmittelechtem Edelstahl, der den Standards für Lebensmittelsicherheit und Hygiene entspricht.

Knoblauch-Dörrgerät

Je nach Dörrleistung kann der Knoblauchdörrer unterschiedliche Trocknertypen verwenden. Es handelt sich um einen multifunktionalen Dörrapparat für Obst und Gemüse. Die Heizenergie kann Strom, Gas, Biomassepartikel, Abfallstoffe usw. sein. Der Knoblauch-Dörrapparat wird über ein intelligentes Bedienfeld bedient, und der gesamte Dörrvorgang wird über ein intelligentes Bedienfeld gesteuert. Die Bedienung ist einfach, die Trocknungsleistung groß und die Temperaturregelung wird automatisch angepasst.

Knoblauchpulver-Mahlmaschine

Die Knoblauchpulver-Mahlmaschine mahlt Knoblauch hauptsächlich durch die Relativbewegung zwischen der beweglichen Zahnscheibe und der festen Zahnscheibe zu Pulver. Die Feinheit des Pulvers ist kontrollierbar. Die Feinheit des von dieser Maschine gemahlenen Pulvers ist gleichmäßig. Außerdem ist der Schleifvorgang geräuscharm und verfügt über eine spezielle Staubsammelvorrichtung. Es ist eine sehr beliebte Maschine in der Lebensmittel- und Pharmaindustrie. Diese Maschine kann Knoblauch, Ingwer, Tee, Pfeffer und andere Produkte mahlen.

Verpackungsmaschine für Knoblauchpulver

Die Knoblauchpulver-Verpackungsmaschine ist eine halbautomatische Wäge- und Füllmaschine für Pulververpackungen. Die Maschine verfügt über die Funktionen Messen, Füllen, Versiegeln und Transportieren. Sie kann je nach Verpackungsmaterialien und Verpackungsform des Kunden verschiedene Beutelklemmstrukturen wählen. Die Maschine wird über einen Touchscreen gesteuert. Der Verpackungsprozess ist automatisiert, und die Verpackungsspezifikationen können angepasst werden.

Merkmale der Produktionslinie für Knoblauchpulver

Hohe Produktionskapazität

Diese Produktionslinie unterstützt eine breite Palette an Ausgangskapazitäten, von Hunderten bis zu mehreren Tausend Kilogramm pro Stunde, abhängig von der Konfiguration. Jede Maschine — vom Knoblauchzehen-Separator bis zu den Mahl- und Verpackungssystemen — kann entsprechend den spezifischen Produktionsanforderungen ausgewählt werden, um einen effizienten Dauerbetrieb und hohe Durchsatzleistung zu gewährleisten.

Hergestellt aus lebensmittelechtem Edelstahl

Alle Maschinen sind aus SUS304 oder SUS316 Edelstahl gefertigt, was den internationalen Lebensmittelhygienestandards entspricht. Dieses Material sorgt für Langlebigkeit, Korrosionsbeständigkeit und sicheren Kontakt mit Lebensmitteln. Es erleichtert auch die Reinigung und Wartung, was eine langfristig stabile Leistung garantiert.

Stabile Struktur und Zuverlässige Leistung

Die gesamte Linie verfügt über eine robuste mechanische Konstruktion mit präzisem Design und niedrigen Ausfallraten. Die Ausrüstung arbeitet reibungslos auch bei schwerer Belastung und langen Arbeitsstunden, was einen stabilen Betrieb und gleichbleibende Produktqualität gewährleistet.

Intelligent und Einfach zu Bedienen

Jede Maschine ist mit intelligenten Steuerpanels und verstellbaren Geschwindigkeitsystemen ausgestattet, die es den Bedienern erleichtern, den gesamten Prozess zu überwachen und zu steuern. Das System unterstützt automatische Temperatur- und Zeiteinstellung während Dehydration und Verpackung, was manuelle Eingriffe reduziert und die Effizienz steigert.

Einheitliche Pulverfeinheit und hohe Produktqualität

Die Knoblauchmahlmaschine verwendet Hochgeschwindigkeitsrotationsklingen mit einstellbaren Maschenweiten (20–120 Mesh), was eine gleichmäßige und feine Pulvertextur gewährleistet. Das endgültige Knoblauchpulver ist trocken, glatt und ideal für die Verwendung in Lebensmittelherstellung, Würzung und Pharmazie.

Modulares Design — Maschinen können separat verwendet werden

Jede Einheit (wie Knoblauchzehen-Separator, Schälmaschine, Waschmaschine, Slicer, Dehydrator, Mahler und Verpackungsmaschine) kann unabhängig betrieben oder zu einer vollständigen Produktionslinie kombiniert werden. Dieses flexible modulare Design ermöglicht es Kunden, ihre Einrichtung entsprechend Budget und Produktionsbedarf anzupassen.

Energieeffizient und umweltfreundlich

Das Dehydrationssystem unterstützt mehrere Heizquellen wie Strom, Gas, Biomassepellets oder Abwärme. Die intelligente Temperaturregelung reduziert Energieverschwendung und erhält gleichzeitig die Trocknungseffizienz, was es kosteneffizient und umweltfreundlich macht.

Kompakte Anordnung und einfache Wartung

Die Linie ist für eine kompakte Installation konzipiert, spart Platz in der Werkstatt. Die meisten Komponenten sind für einfache Demontage und Reinigung ausgelegt, was Ausfallzeiten und Wartungskosten minimiert.

Hohe Kosten-Leistungs-Verhältnis

Im Vergleich zu importierten Verarbeitungssystemen bietet diese Linie eine hervorragende Leistung bei geringeren Investitionskosten. Ihr stabiler Betrieb, einfache Wartung und lange Lebensdauer bieten bedeutende wirtschaftliche Vorteile für Knoblauchverarbeitungsfabriken.

Breit anwendbar

Die Knoblauchpulver-Produktionslinie kann auch andere Materialien wie Ingwer, Zwiebel, Chili, Kurkuma und schwarzen Pfeffer verarbeiten, was die Nutzung und Flexibilität des Geschäfts erhöht.

Verwendung von Knoblauchpulver

Knoblauchpulver ist ein äußerst beliebtes natürliches Gewürz und funktionelles Ingredient auf dem globalen Markt. Es wird weit verbreitet in der Lebensmittelindustrie, im Catering, im Gesundheitswesen, in der Landwirtschaft und in anderen Branchen verwendet – insbesondere in Regionen wie Europa, den Vereinigten Staaten, Südostasien und dem Nahen Osten.

Lebensmittelindustrie

- GewürzmischungenHäufig verwendet in Knoblauchsalz, Knoblauchpfeffer, BBQ-Gewürzmischungen und Gewürzmischungen wie italienischen Gewürzen oder mexikanischen Gewürzmischungen. Es ist ein wichtiges Exportprodukt.

- Fertiggerichte: Wird zu Pizza, Burgern, frittiertem Hähnchen, Pommes Frites, Instantnudeln, Suppen, Salatdressings und mehr hinzugefügt, um den Geschmack zu verbessern.

- Tiefkühlkost: Weit verbreitet in vorgekochten Mahlzeiten. Knoblauchpulver ist ein wichtiges Gewürz in vielen gefrorenen Gerichten, die in Supermärkten in den USA und Europa verkauft werden.

Restaurantketten

- Beliebt bei großen Fast-Food-Marken (wie KFC oder Subway), Restaurants des Nahen Ostens und lateinamerikanischen BBQ-Ketten.

- Wird in großen Mengen zum Würzen und Marinieren verwendet, ersetzt frischen Knoblauch, um die Vorbereitungszeit zu verkürzen und den Geschmack konstant zu halten.

Gesundheitspräparate

- In westlichen Ländern wird Knoblauchpulver oder -extrakt in Kapseln und Tabletten hergestellt, die für die Herzgesundheit, antibakterielle Wirkungen, antioxidative Eigenschaften und Cholesterinkontrolle beworben werden.

Futtermittelindustrie

- In Europa und Lateinamerika wird Knoblauchpulver zunehmend als natürliche Alternative zu Antibiotika in Tierfutter verwendet. Es hilft, die Immunität zu stärken und die Verdauung bei Geflügel, Schweinen und Fischen zu verbessern.

Biologische und umweltfreundliche Landwirtschaft

- Wird zur Herstellung von natürlichen Pestiziden und Desinfektionsmitteln verwendet, ideal für Bio-Bauernhöfe. Es hilft, den Einsatz chemischer Mittel zu reduzieren und unterstützt umweltfreundliche Landwirtschaft.

Bestsellerländer für Knoblauchpulver

Knoblauchpulver ist in den folgenden Ländern und Regionen am beliebtesten, mit hoher Marktnachfrage und breiten Anwendungen:

- Vereinigte Staaten

- Indien

- Brasilien

- Mexiko

- Deutschland

- Japan

- Länder des Nahen Ostens (z. B. Saudi-Arabien, VAE)

- ……

Liste der Referenzmodelle der Hauptmaschinen

Knoblauchzehen-Separatormaschine

- Modell: SL-Serie

- Knoblauchpulver-Verpackungsmaschine | Automatische Knoblauchpulver-Verpackungsmaschine 400 – 1000Kg/h

- Leistung: 1,1 kW oder 2,2 kW

- Spannung: 380V

- Dimension: Gemäß den spezifischen technischen Spezifikationen

Knoblauchschälmaschine

- Modell: SL-200; SL-400; SL-600; SL-1000

- Spannung: 110-220-380V

- Gewicht: 150KG; 250KG; 350KG; 500KG

- Ausgang: 200kg/h; 400kg/h; 600kg/h; 1000kg/h

- Größe: 130*55*140CM; 162*55*140CM; 182*60*140CM; 280*98*170CM

Knoblauchreinigungsmaschine

- Knoblauchpulver-Verpackungsmaschine | Automatische Knoblauchpulver-Verpackungsmaschine 500 – 2000Kg/h

- Material: Knoblauch-Lufttrocknungsmaschine

- Leistung: Anpassbar

- Größe: Gemäß den spezifischen technischen Spezifikationen

Knoblauchslicer-Maschine

- Modell: Knoblauchpulver Verpackungsmaschine | Automatische Knoblauchpulver Verpackungsmaschine 1

- Abmessung:Knoblauchlufttrocknungsmaschine

- Knoblauchpulver-Verpackungsmaschine | Automatische Knoblauchpulver-Verpackungsmaschine 300kg/h

- Material: SS304/SS316

- Gewicht: Fall

- Leistung:Knoblauchpulver Verpackungsmaschine

Knoblauch-Dehydrator

- Modell: SL-Serie

- Knoblauchpulver-Verpackungsmaschine | Automatische Knoblauchpulver-Verpackungsmaschine 300 – 8000Kg/h

- Leistung: Anpassbar

- Größe: Gemäß den spezifischen technischen Spezifikationen

Knoblauchpulver-Mahlmaschine

- Modell: SL-B-Serie

- Knoblauchpulver-Verpackungsmaschine | Automatische Knoblauchpulver-Verpackungsmaschine 20 – 3000Kg/h

- Zerkleinerungsfeinheit: 20-120 Mesh

- Motorleistung: 2,2-37KW

- Drehzahl der Spindel (U/Min): Siehe technische Parameter

- Fütterungsgröße: 6-15mm

Knoblauchpulver-Verpackungsmaschine

- Verpackungsgeschwindigkeit: Was ist das Arbeitsprinzip der SL-800 Knoblauchreinigungsmaschine?

- Beutellänge: Knoblauch-Lufttrocknungsmaschine

- Beutelse width: Was ist das Arbeitsprinzip der SL-800 Knoblauchreinigungsmaschine?

- Füllbereich: innerhalb von 80g

- Stromverbrauch: 2,2 kW

- Abmessungen: 650*1050*1750mm

FAQ – Knoblauchpulver-Produktionslinie

Was ist die Produktionskapazität der Knoblauchpulverlinie?

Je nach Konfiguration liegt die Ausgabe zwischen 400 kg/h und 8000 kg/h. Jede Maschine kann an unterschiedliche Produktionsbedürfnisse angepasst werden, von kleinen bis zu groß angelegten Betrieben.

Aus welchem Material besteht die Ausrüstung? Ist es lebensmittelecht?

Alle Maschinen sind aus lebensmittelechtem SUS304 oder SUS316 Edelstahl gefertigt, was korrosionsbeständig, leicht zu reinigen und vollständig konform mit internationalen Lebensmittelhygienestandards ist.

Kann diese Produktionslinie andere Materialien außer Knoblauch verarbeiten?

Ja. Es kann auch zur Verarbeitung von Ingwer, Zwiebel, Chili, Kurkuma, schwarzem Pfeffer und anderen Wurzel- oder Gewürzmaterialien verwendet werden, was es zu einer vielseitigen Investition macht.

Kann die Feinheit des Knoblauchpulvers eingestellt werden?

Ja. Der Pulvermahlwerk ermöglicht einstellbare Maschenweiten von 20 bis 120 Mesh, was die Produktion von grobem und feinem Knoblauchpulver ermöglicht.

Welche Heizmethoden gibt es für die Dehydrationsmaschine?

Der Dehydrator unterstützt mehrere Heizquellen, wie Strom, Gas, Biomassepellets oder Abwärme, die je nach lokaler Energieverfügbarkeit ausgewählt werden können.

Ist der Betrieb kompliziert? Brauche ich geschulte Techniker?

Keineswegs. Die Linie verwendet intelligente Steuerungspanels für Temperatur, Zeit und Geschwindigkeitsanpassung. Nach grundlegender Schulung können Bediener den gesamten Prozess leicht verwalten, ohne einen spezialisierten Techniker zu benötigen.

Können die Maschinen separat gekauft werden?

Ja. Jede Maschine — einschließlich des Knoblauchzehen-Separators, Schälers, Slicers, Waschers, Dehydrators, Mahlers und Verpackungsmaschine — kann separat verkauft oder als Teil einer vollständigen Produktionslinie verwendet werden.

Was sind die Hauptanwendungen des endgültigen Knoblauchpulvers?

Knoblauchpulver wird breit in Lebensmittelwürzung, Fast-Food-Ketten, Nahrungsergänzungsmitteln, Tierfutter und biologischer Landwirtschaft verwendet. Es ist ein nachgefragtes natürliches Gewürz auf globalen Märkten.

Ist die Ausrüstung leicht zu reinigen und zu warten?

Ja. Die Maschinen verfügen über eine kompakte Struktur und abnehmbare Designs, die eine schnelle Reinigung und niedrige Wartungskosten ermöglichen, während sie eine langfristig stabile Leistung sicherstellen.

Kann die Knoblauchpulver-Produktionslinie angepasst werden?

Absolut. Shuliy bietet maßgeschneiderte Lösungen basierend auf Ihrer erforderlichen Kapazität, Anlagenlayout, Spannung, Verpackungsart und Heizquelle, um eine optimale Produktionseffizienz zu gewährleisten.

Kooperieren Sie mit uns

Bei Interesse kontaktieren Sie uns bitte direkt über WhatsApp für weitere Details: https://wa.me/+8619139761487

Heißes Produkt

Produktionslinie für Knoblauchpulver

Die Knoblauchpulver-Produktionslinie umfasst hauptsächlich Knoblauch…

Knoblauch-Trocknungsmaschine | Knoblauch-Gürtel-Trockner

Knoblauch-Dehydrator wird allgemein bekannt als ein…

Knoblauchsortiermaschine

Kommerzielle Knoblauch-Sortiermaschine verwendet Zylinder zur Klassifizierung…

Knoblauchpflanzmaschine

Die Knoblauchpflanzmaschine ist ein landwirtschaftliches Gerät…

Manuelle Knoblauchernte-Maschine

Knoblauchernte-Maschine hilft Landwirten beim Ernten von Knoblauch…

Knoblauchschneidemaschine

Knoblauchschneider hohe Leistung, multifunktional, einfache Steuerung von…

Knoblauch-Ketten-Entfernungsmachine | Kommerzieller Knoblauchschäler

Die kettenbasierte Knoblauchschälmaschine ist speziell entworfen…

Knoblauch-Dehydrator | Industrieller Knoblauch-Trocknungsofen

Knoblauch-Dehydrationsmaschine ist eine Heißluftzirkulations…

Doppelriemen-Knoblauchwurzel-Konkavschneidemaschine

Die konkave Knoblauchwurzel-Schneidemaschine entfernt die…