Es liegt ein Fehler bei der Verwendung der Knoblauchsortiermaschine vor! Es stellte sich heraus, dass es der Grund dafür war!

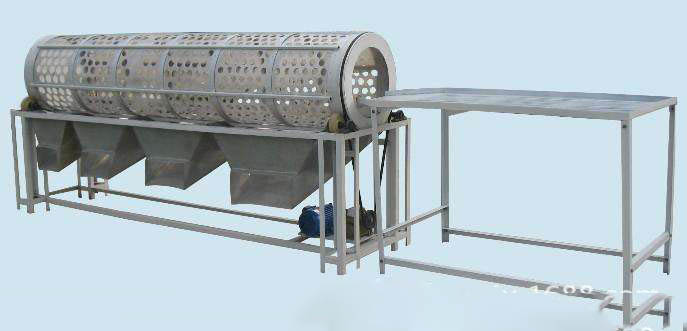

In unseren aktuellen Arbeitsanwendungen wird die praktische Anwendung der Knoblauchsortiermaschine immer umfangreicher und gewinnt zunehmend an Bedeutung. Der Einsatz von Knoblauchsortier -Geräten reduziert den Arbeitskräfteaufwand und die Zeitverschwendung erheblich. Allerdings sind Fehlerseiten bei den Knoblauchsortiergeräten oft unvermeidlich. Was sind die Gründe für diese Fehler? Hier sind einige Ursachen für Fehler bei mehreren Knoblauchsortiergeräten.

Unangemessene Struktur des Knoblauchsortier-Geräts führt zu Messfehlern

Damit der Sensor des Knoblauchsortiergeräts einheitlich arbeitet, sollte der Schwerpunkt des Aggregats und der Trichter auf einer vertikalen Linie liegen. Tatsächlich ist das Aggregat kein homogenes Material, und der Fehler bei der Gestaltung und Herstellung des Behälters selbst führt dazu, dass der theoretische Schwerpunkt und der tatsächliche Schwerpunkt nicht übereinstimmen, was zu Fehlern bei der Ungleichheit der drei Sensoren führt. Selbst wenn der Schwerpunkt des Trichters selbst nicht verschoben ist, kann es während des Zuführprozesses zu einem Messfehler kommen, da der Schwerpunkt des Aggregats verschoben wird. Daher sollte der Schwerpunkt des Trichters nicht verschoben sein, und der Trichter kann durch Eigengewicht ausgeglichen werden, um den Schwerpunkt des Aggregats und den Schwerpunkt des Behälters auf einer Linie zu halten.

Wenn Sie Fragen zum Knoblauchsortierer haben, zögern Sie bitte nicht, uns zu kontaktieren.